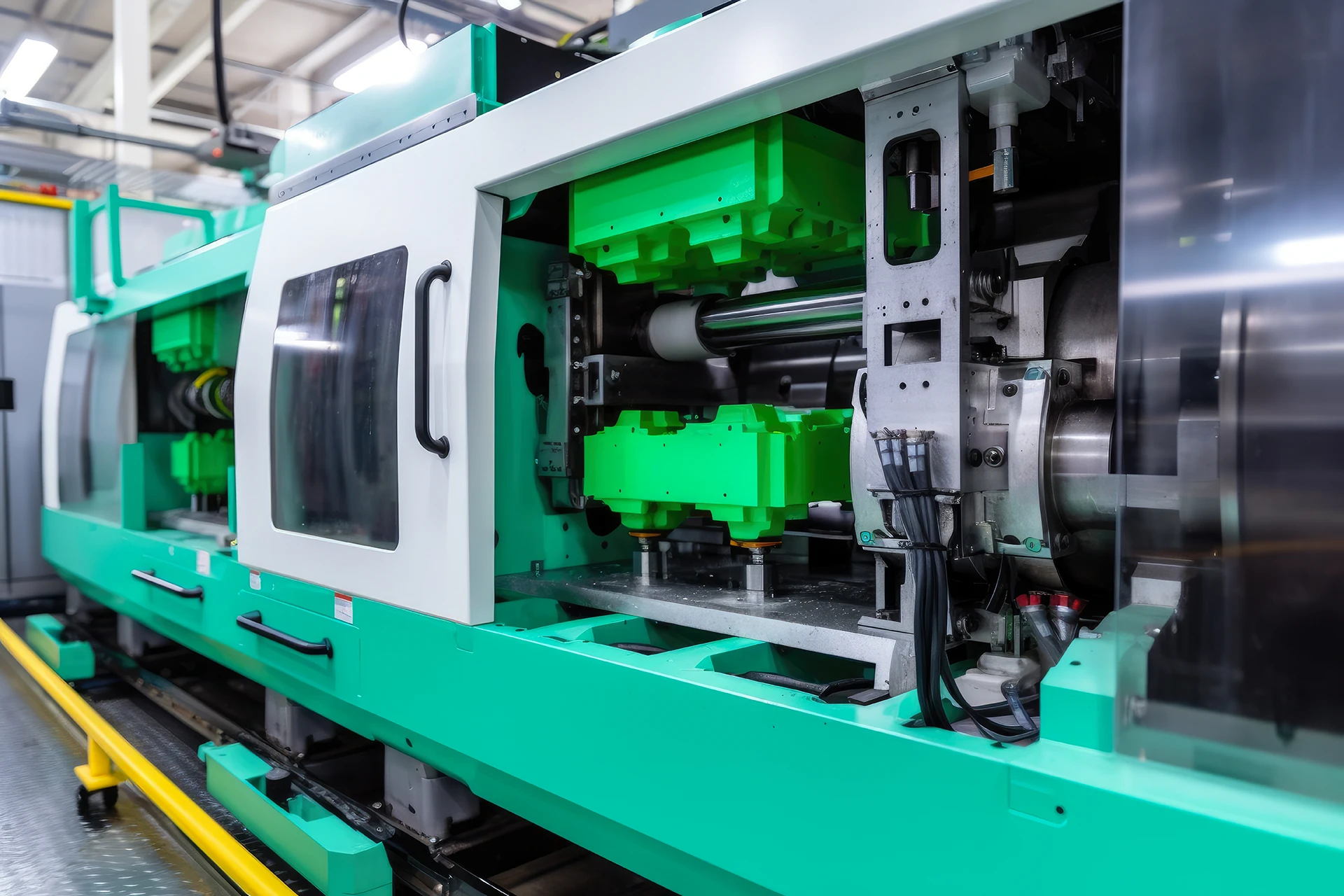

Plastics in machine construction

Plastics play an essential role in machine construction due to their unique properties that contribute to improved performance, efficiency, and cost savings. Their lightweight, wear resistance, and design flexibility make them an ideal alternative to traditional materials such as metal. Additionally, plastics offer advantages such as reduced wear, lower friction, and excellent insulation, leading to more durable and reliable machines.

Key Properties of Plastics in Mechanical Engineering

Weight Reduction: Plastics are often much lighter than traditional materials like steel and aluminum. This reduced weight lessens the strain on moving parts, potentially enabling higher speeds, lower energy consumption, and improved machine efficiency.

Wear and Corrosion Resistance: Many plastics are resistant to wear and corrosion, making them ideal for components that come into contact with abrasive materials, chemicals, or moisture. This enhances the lifespan of machine parts and reduces the need for frequent replacement or maintenance.

Low Friction and Self-Lubricating Properties: Certain plastics, such as polyethylene (PE) and polytetrafluoroethylene (PTFE), have inherent lubricating properties and a low coefficient of friction. This makes them suitable for components like bearings, gears, and slide plates, which require minimal external lubrication and operate more quietly and efficiently.

Insulation and Protection: Plastics are excellent insulators for both electricity and heat, making them suitable for use in electrical insulation components and thermal barrier applications. This improves machine safety and reliability by preventing short circuits and protecting temperature-sensitive parts.

Design Flexibility and Customization: Plastics can be molded into complex shapes and easily tailored to specific requirements, enabling designers to create custom machine parts that perform optimally in their specific applications. This also allows for rapid prototyping and quick adjustments.

Summary

In summary, plastics contribute to innovation and efficiency in mechanical engineering through their lightweight nature, wear resistance, low friction, insulating properties, and design flexibility. These qualities lead to improved performance and reduced costs in industrial applications.

Curious about the plastics Profplastic supplies to the mechanical engineering sector? Contact us today!