Properties and Benefits of Plastics in the Automotive Industry

- Weight Reduction: Plastics are much lighter than traditional materials like metal. This reduces the weight of vehicles, leading to lower fuel consumption, higher energy efficiency, and reduced CO2 emissions, which helps meet stringent environmental regulations.

- Cost Reduction: Plastics are often cheaper to produce and process than metals. By using plastics, manufacturers can lower production costs, resulting in lower retail prices and higher profitability.

- Design Freedom and Versatility: Plastics can be easily molded into complex shapes, providing more flexibility in the design of automotive components. This enables the production of innovative, aerodynamically shaped vehicles that enhance both aesthetics and performance.

- Safety and Comfort: Plastics are used in numerous safety features, such as airbags and dashboard structures that absorb energy in the event of a collision. They also help with sound and temperature insulation, contributing to a quieter and more comfortable driving experience.

- Durability and Maintenance: Many plastics are resistant to corrosion, chemicals, and weather conditions, leading to longer-lasting vehicle parts and less maintenance. Additionally, some plastics can be recycled, contributing to the sustainability of the automotive industry.

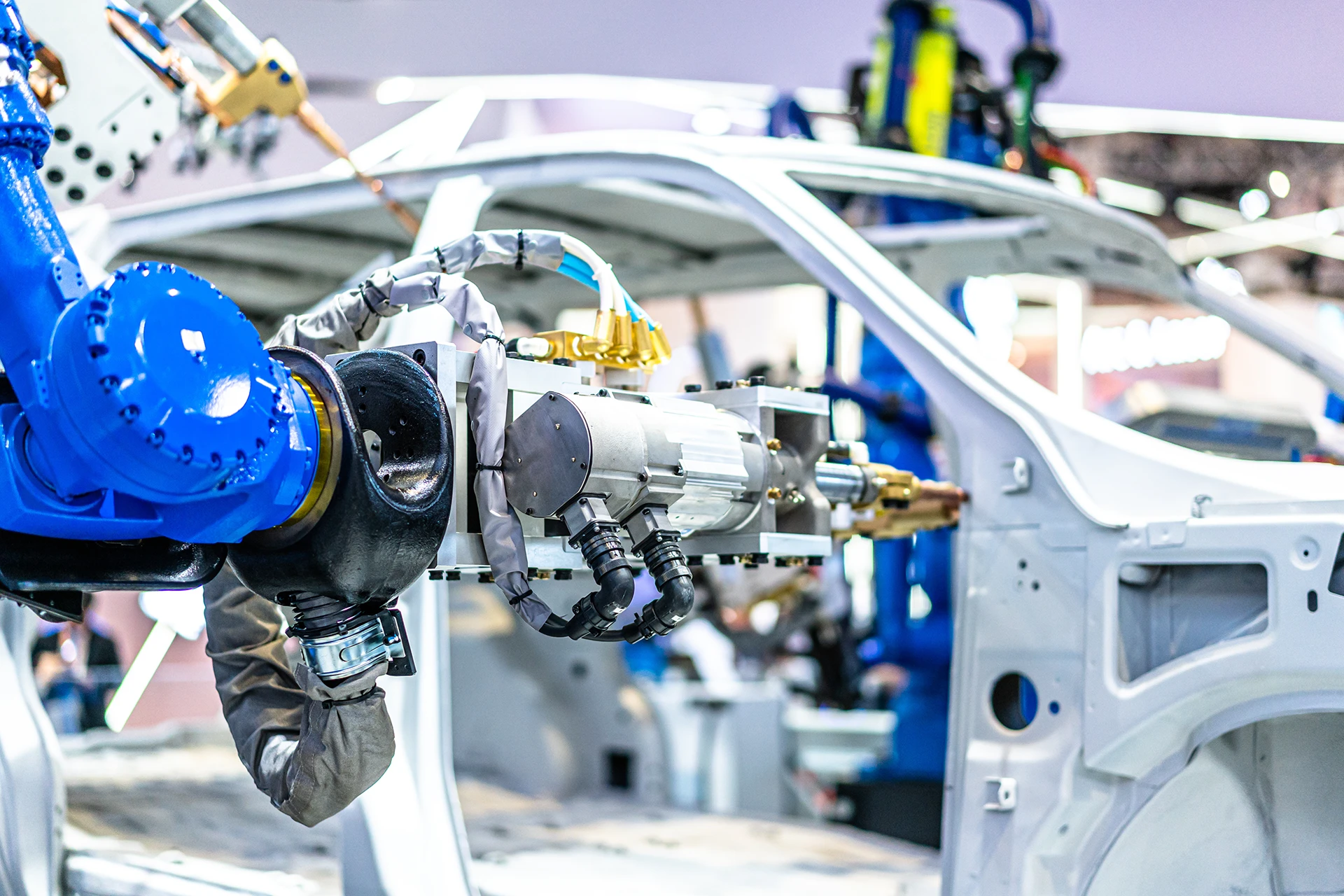

Plastics Used in the Automotive Industry

A selection of plastics used by Profplastic for automotive applications includes:

- POM C

- PEEK

- PA6

- PI

- PES

- PTFE

- HMPE

- PETP

Curious about the plastics that Profplastic supplies to the automotive industry? Feel free to contact us!