Welding

Your partner in plastic welding technology

Are you looking for a specialist in seamlessly and strongly bonding plastic components? At Profplastic, we combine modern welding equipment with years of expertise to bring even the most challenging projects to life. Whether it’s an industrial tank or a jacuzzi! What seems impossible, we make possible

What we do

What we do

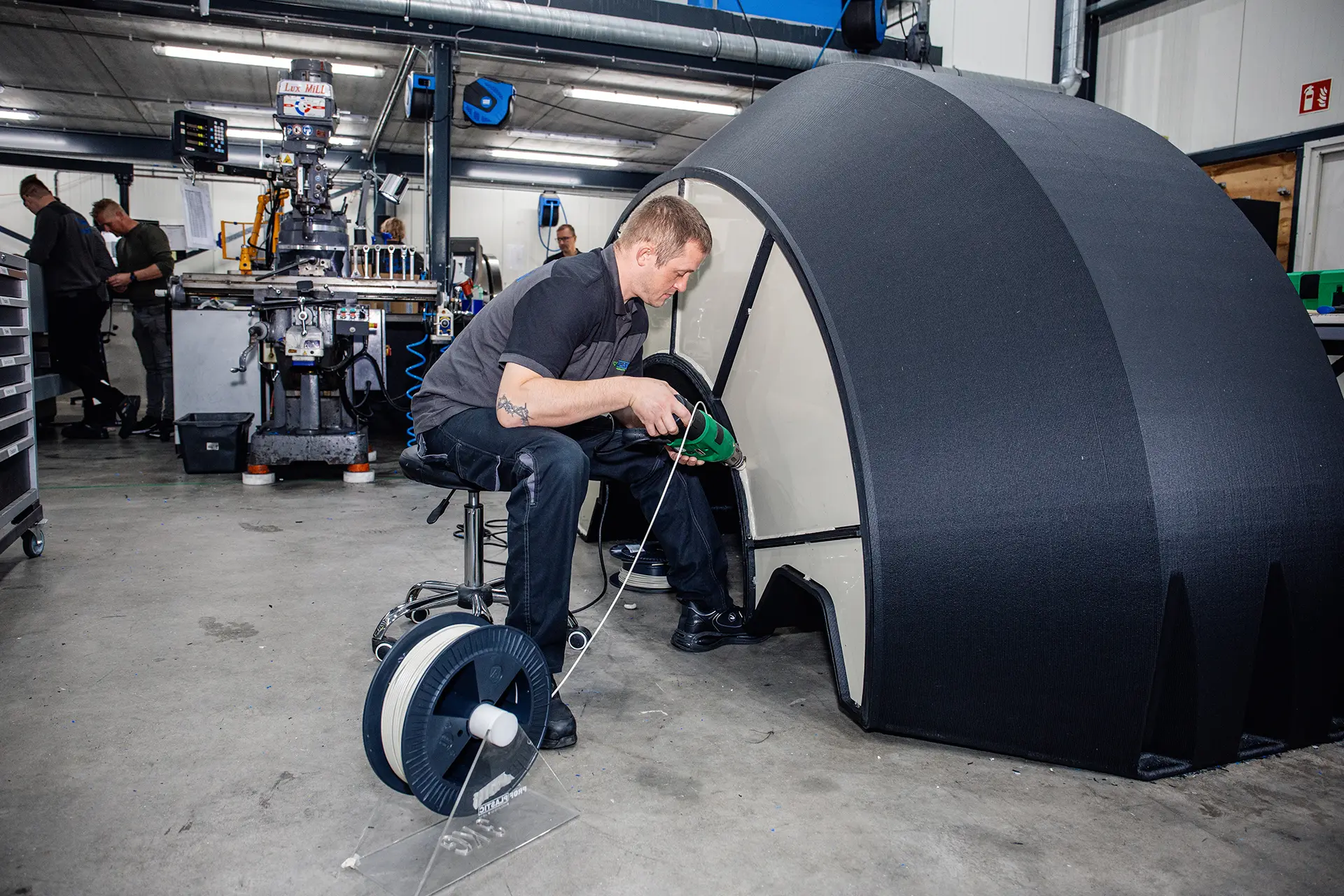

Extrusion welding

At Profplastic, we use state-of-the-art extrusion machines to create optimal plastic bonds. By carefully heating the plastic and precisely pressing it into the weld seam, we achieve exceptionally strong connections for your product.

Wire welding

With our advanced wire welding technique, we heat a plastic welding rod made from the same material and let it flow into the weld seam. This allows it to seamlessly bond with the surrounding plastic. This technique enables Profplastic to achieve ultimate precision for smaller and more detailed connections.

Why welding technology at Profplastic?

Why welding technology at Profplastic?

At Profplastic, our specialists proactively think along with you, from the initial design to the final product. With our in-depth knowledge of welding techniques and material properties, we provide the best solution for your project.

What else do we offer?

- We have the capability to machine water buffer tanks, jacuzzis, swimming pools, and pump enclosures into a kit, which we then weld together for an outstanding final result.

- We offer the option to reinforce plastic components withsteel reinforcements coated in plastic, ensuring optimal strength with minimal material thickness—making it both durable and cost-efficient!

- The weld seams we create are highly resistant tointensive use, wear, and environmental factors, ensuring maximum durability for your plastic components.

- Whether it’ssmall, intricate parts or large-scale applications, we provide welding solutions that perfectly match the requirements of your project.

Your extrusion or wire welding project starts here!

Your extrusion or wire welding project starts here!

Would you like to know how our welding technologies can take your project to the next level? Our experts are ready to advise you on the best solutions for your specific application – we have the knowledge.